Product

All categories

JD3110 series fully automatic water injection insulating boots and gloves withstand voltage and leakage current test bench

The automatic water injection test platform can perform withstand voltage tests on insulating boots, insulating gloves, and insulating hats.

Category:

Email:

Messages

Product description

Product Introduction

The automatic water injection testing platform can perform withstand voltage tests on insulating boots, insulating gloves, and insulating caps.

Main Features

- The testing platform can simultaneously perform withstand voltage tests on 8 insulating boots or gloves, or 6 insulating caps.

- Insulating boots can undergo both wet and dry tests. During wet tests, the insulating boots are submerged in water, and the inner electrode is filled with water; during dry tests, the outer electrode is equipped with a water-soaked sponge, and the inner electrode is manually filled with steel balls.

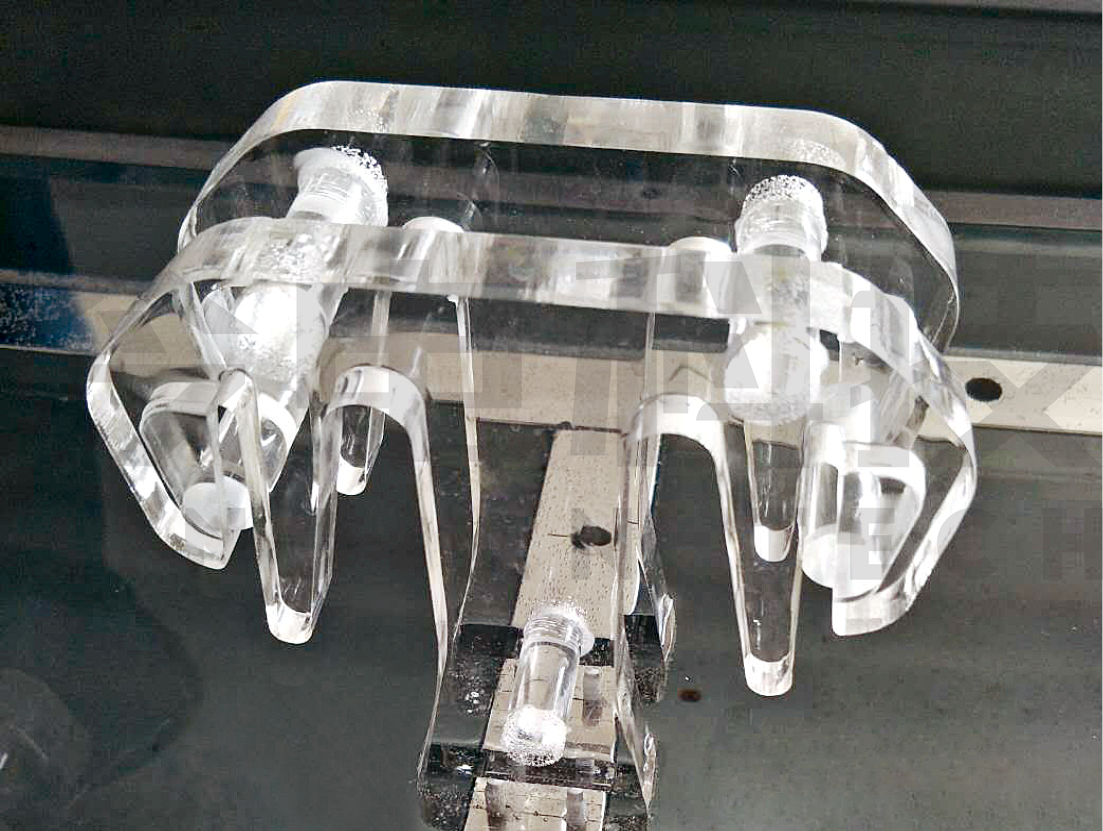

- The insulating gloves are fixed using a high-polymer insulating material "swan neck" patented technology. The two sides of the gloves are clamped in the swan neck for precise positioning to facilitate automatic water injection. The clamping mechanism has no conductive components, meeting insulation requirements. After the test, the swan neck can be easily removed to take off the insulating gloves.

- The water injection tube has a special design with a columnar water flow. The water injection tube injects water into the inside of the glove, preventing water from splashing onto the inner wall of the glove and reducing the creepage distance on the glove surface. Once water injection is complete, it retracts into the top of the platform to ensure insulation distance.

- It has an insulating cap testing placement slot; the test item can be fixed for testing.

- Each test item in the high-voltage control unit has a fast high-voltage disconnection mechanism. When any channel breaks down, that test item will automatically disconnect from the high voltage without affecting the progress of the test.

- The high-voltage control unit of the test bench uses an 8-channel AD converter to measure the leakage current. Through infrared communication technology, the data is transmitted to the main test bench control system for display, processing, and storage.

- The high-voltage control unit is powered by a lithium battery. When the test item is being filled with water, the high-voltage control unit rises to the top, automatically grounding and connecting to the charging electrode for automatic charging.

- During the testing process, the test bench uses LED digital tubes to display parameters such as the leakage current of the 8 test items.

- The testing platform uses a 7-inch color LCD touch screen for operation. By selecting the test items and parameters, fully automatic operation is achieved.

- The testing platform has multiple detection functions, including water level detection in the tank, test item position detection, test tray position detection, and test item height detection, ensuring smooth water injection.

- The testing platform software can set different test item parameters. Based on these parameters, the testing platform automatically sets the distance from the glove cuff to the water surface according to the standard, while ensuring that the inner and outer water levels are consistent.

- Insulating cap testing can determine the inner and outer water levels of the insulating cap, ensuring the creepage distance at the cap mouth and ensuring that the inner and outer water levels are consistent.

- The test bench and control console have an interlock device to ensure the safety of the test personnel.

Technical Parameters

|

Rated Voltage |

50kV |

| Leakage Current Range |

25.0mA |

| Leakage Current Measurement Error |

<1.0% reading ±1 digit |

|

Leakage Current Resolution |

0.01 mA |

| Digital Timer |

10~990 S |

| External Dimensions | 2200×720×1890(mm) |

| Weight | 260kg |

Recommended products

SAUNDERS

If you have any suggestions or feedback on our company, please fill in the relevant information on this page and submit it. A staff member will contact you in time, or please call us directly.